As a dropshipper, have you ever wondered how the process behind your order is? Which steps does it require to fulfill the order? In today’s article, we followed a real case from CJ’s orders, aim to use this case study to portray a vivid example of the order-fulfillment process for you.

Case Background

Alex: Lives in Canada, has a 9 to 5 job.

Has an online clothing store that sells goods to the United States in order to earn some extra money to improve his living quality.

Dylan: Lives in the US, placed an order for short-finger cycling gloves in Alex’s shop.

For quicker shipment, he chose DHL for fast delivery.

Since Alex doesn’t live in the States and doesn’t have local suppliers, he chose CJdropshipping to fulfill Dylan’s order.

This case is not complicated but very typical to present the process behind all the other hundreds of thousands of orders CJ receives every day.

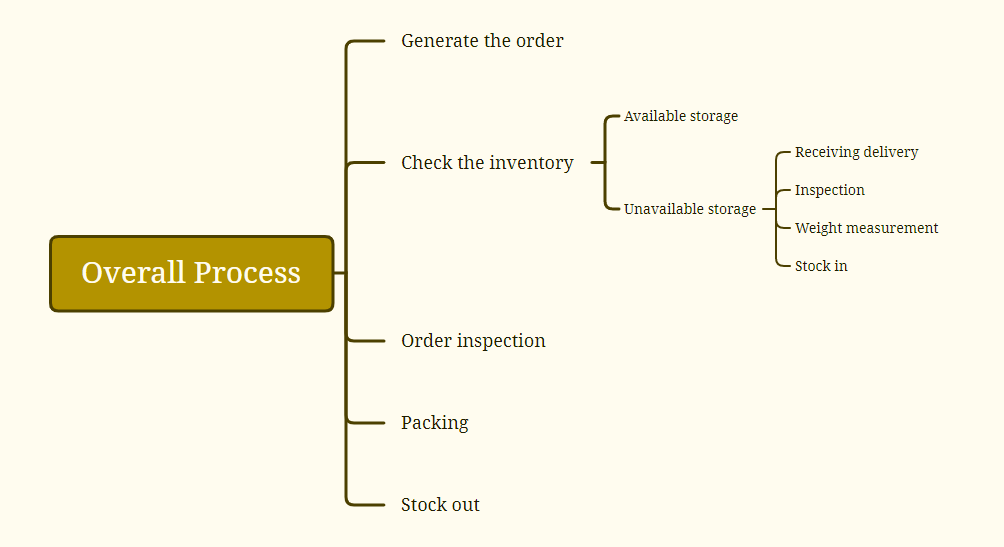

The Process

Step 1 Generate the order number

When CJ receives customers' orders, we will generate order numbers and batch numbers for these orders which usually will be done within 24 hours. The order number is what we label on the shipping bag, and it presents all the information of one package, including the recipient's address, what’s inside the package, its weight, etc. And the batch number is used for scanning, which helps our staff to find the matching good efficiently.

Step2

When it comes to step2, there are two scenarios.

Scenario 1 Storage available

After the batch number and order number are generated, we found the gloves Dylan wanted are available in the warehouse, we then move to the storage section to pick them up. Every product is well organized by category and stored on shelves. We use a bar-code reader to scan the bar-code we just generated and it will show where the gloves are stored. When we find the gloves Dylan wanted, we scan the bar-code labeled on the packaging again to indicate this inventory is used.

Scenario 2 Storage not available

After generating the order number, what if CJ’s warehouse doesn’t have the short finger cycling gloves that Alex sells. Then what will happen? Here is a hypothetical scenario: Alex placed an order on CJ for Dylan, then we generated the order number but find out we don’t have the gloves in stock. In that case, procurement staff will receive a purchasing list states they need to purchase Dylan’s gloves and where to buy them. According to the list, they will place an order with local manufacturers and wait for the package to arrive at the CJ warehouse.

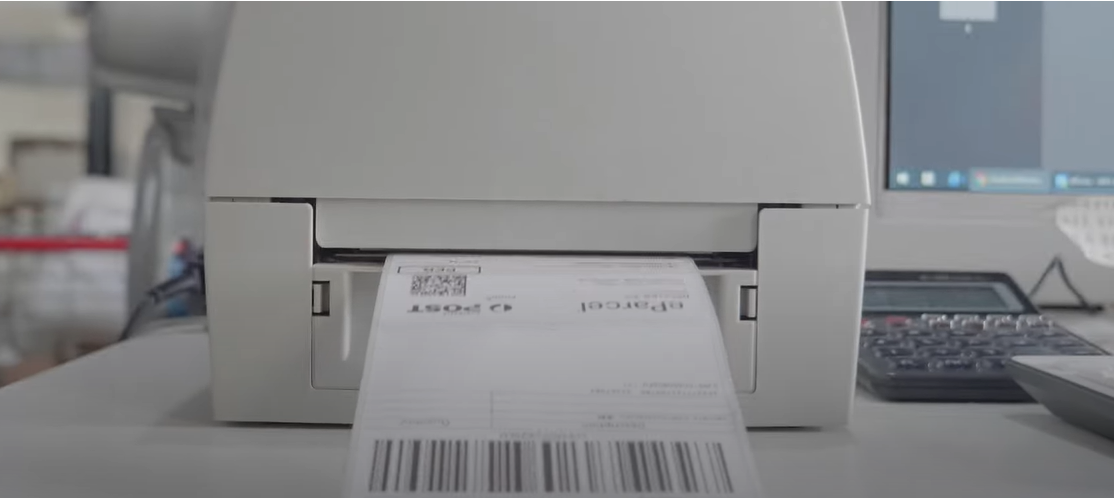

- Receiving delivery: After 1-3 days, depending on how far the manufacturer is located, a bunch of packages arrived at the CJ warehouse at the recipient area, where we store signed packages from manufacturers. The staff will scan the code on the package to see what’s inside the bag and check whether the item matches what we ordered in the system. Our staff will print out the bar code, put both the bar-code and the good in the basket, and send it to the quality inspection department.

- Inspection: After scanning the bar code, our system will show the product detail, like the color, size, function, etc. So our quality inspector will check through the product from in and out according to the product description shown on the system. Usually, there will be 2 rounds of quality checks for every product to avoid inferior products.

- Weight measurement: After inspection, the product will be handed to the next process - weight measurement. Place the gloves at the scale to get the actual weight, use the bar-code reader to scan the product to find the product in the system, and enter the actual weight. This step can help to estimate the shipping cost more accurately.

- Stock in: Now Dylan’s gloves have passed all the inspection and are ready to be stored on the shelf with other products. Scan the bar-code on the gloves, and the bar-code reader will show where these gloves should be stored. Then we go find the right shelf and scan both the bar code on the product and the shelf to record that we have placed these gloves in stock.

Step 3 Order inspection

After finishing pick out the gloves, move to the next step - order inspection. Our inspector will scan the bar-code on the product again to obtain all the order information in this step. Our staff will verify the order for Dylan, make sure it is the right product Dylan ordered. When everything checks out the staff will print out the shipping label, pack gloves inside the shipping bag, put the shipping label on it, and pass it to the conveyor belt.

Step 4 Packing

Dylan’s gloves are pretty small and really easy to pack, but not all the products are like this. So for these products, it will go to the packaging section. On the other side of the conveyor belt, the packing team is packing products according to their features.

Step 5 Stockout

Many more packages that passed inspection like Dylan’s will get well packed and be on the conveyor belt, waiting to be sorted out. Someone pick it up and place it on the scale to double-check the weight and parcel size and group it to the DHL basket. This scale will automatically detect the parcel and compare the actual weight(packaging included) to the weight price we charged from Alex. 50g minus or plus difference are all acceptable. Every parcel will pass through this step and group to different baskets marked by different logistic providers.

Our staff will scan Dylan’s parcel and the rest of the parcels from the basket and placed them in a giant box, and wrapped to avoid potential damage on the road. After that, we put on the shipping labels for the whole box. It can make sure logistic providers won’t lose the box and can safely pass every transit. When all the DHL orders from the day are packed into big boxes and labeled, they will be transported to the waiting area, waiting for the DHL driver to pick up the goods.

Conclusion

Every day, many products get well packed in the waiting area, waiting for carriers to pick them up and ship worldwide, and eventually get handed to our customers. The same goes for Dylan’s package, and it will be handed to him soon. 5 days after placing the order, Dylan received his gloves, just like CJ’s goal: dropshipping from worldwide to worldwide and we continuously looking for more satisfaction from customers.

.jpg)